Send us your project information and our Sales & Engineering team will be in touch with you the same day.

Request A Quote

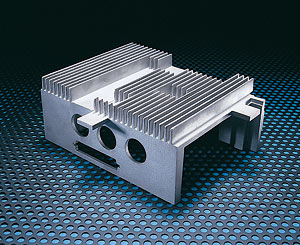

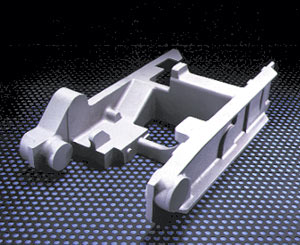

Sand Casting

Spectron provides custom sand castings that can be produced with a variety of surface finishes, dimensional precision, finish allowances and draft. We work closely with our customers to deliver the precise specifications and high quality components they require, on-time and on-budget. We can assist in:

- Advising on the best alloy solutions for a given application.

- Aiding in design for manufacturing characteristics to ensure cost is minimized and the bridge to production is smooth.

- Managing casting and post machining requirements.

- Providing a turn-key product by managing sub assembly and secondary finishing services.

Sand Casting Characteristics

Sand casting utilizes expendable sand molds to form metal parts that can be made of nearly any alloy. A relatively low tooling cost makes it dynamic to tooling modifications and well suited for both prototype and production quantities. Sand casting is a often the most cost effective casting process for larger part sizes (over 20” in any one dimension or more than 30 lbs).

- Tooling ready in 4 weeks

- Typical tooling costs of under $5k

- No minimum quantity requirement, ideal for both prototype and production

- Gravity pour & low pressure processes available

- Excellent mechanical properties, good for MIL Spec requirements

Materials

We routinely pour a broad range ferrous and non-ferrous alloys. The following are some of the most common materials being used:

- Aluminum

- Zinc

- Cast Iron

- Ductile Iron

- Various steel alloys

Design Criteria

- 2 degree draft requirement

- Low pressure process minimum wall thickness of .075”

- Gravity pour process minimum wall thickness of .150”

- Typical surface finish Ra 250-500 micro-inch

- 14 ton weight capacity

What our customers say

“Several years ago we were in search of a supplier of steel sand castings that would be reliable in service, quality, delivery, and price. From day one Spectron Manufacturing has proved to be an excellent supplier and consistently delivers a quality product in a timely manner.”

Preferred Vendor For