Send us your project information and our Sales & Engineering team will be in touch with you the same day.

Request A Quote

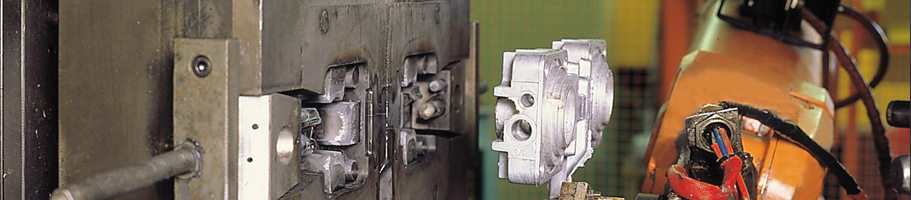

Aluminum Casting

Aluminum Casting Processes

- Production Die Casting

- Soft Tool Die Casting

- Permanent Mold Casting

- Sand Casting

- Investment Casting

- RP Investment Casting

- Plaster Casting

Aluminum Production Die Casting

Aluminum die casting is an excellent source for higher quantity casting requirements. A larger upfront tooling investment yields a significant reduction in reoccurring casting costs. Production die cast aluminum castings have very repeatable properties and tolerances.

Aluminum Soft Tool Die Casting

The term “Soft Tool” is used to describe a aluminum casting tool made out of P-20 steel. The P-20 steel is softer than H-13 steel and thus yields parts in less time with a decrease in tooling cost. This is attributed to the ability to run faster feed rates when CNC machining the tool. Typically a P-20 aluminum casting tool can yield 10,000-40,000 castings before showing any significant wear.

Aluminum Permanent Mold Casting

Aluminum permanent mold casting is an excellent solution for low volume casting requirements (1,000-5,000). A permanent mold casting looks very similar to an aluminum die casting. The main benefit of permanent mold casting compared to die casting is a significant reduction in tooling cost.

Aluminum Sand Casting

Aluminum sand casting can be a good fit for mid to high quantity casting requirements and often the most cost effective for larger component sizes (over 20” in any one dimension or more than 30 lbs).

Aluminum RP Investment Casting

RP (Rapid Prototype) investment casting can be an excellent alternative to CNC machined, SLA, or SLS prototypes. RP investment casting is the only aluminum casting process that is both cost effective at low quantities and yields aluminum casting properties.

Aluminum Investment Casting

Aluminum investment casting can be an excellent fit for mid to high aluminum casting quantity requirements. It is good for casting requirements when the geometry cannot be made using other aluminum casting processes. Compared with RP investment casting, production investment casting requires a higher upfront investment with a much lower reoccurring casting costs. Investment casting has fewer design constraints than traditional cope and drag casting processes.

Aluminum Plaster Casting

Aluminum plaster casting is a very similar process to sand casting, but yields a much better aluminum casting surface finish which is very similar to a die cast finish. Plaster casting is often used for casting quantities of 50-300 to prototype a future die casting. Plaster casting also has the capability of aluminum casting wall thicknesses as thin as .030”.

What our customers say

“Without Spectron our project would not have been as successful as it was. They demonstrated the teamwork, knowledge, and ‘can-do’ attitude needed to pull off a difficult order.”

Preferred Vendor For